Surface Profile Measurement of Blasted Surfaces and More…

Surface profile and coating thickness probes can be easily interchanged with the FISCHER FMP series of instruments. This dual capability instrument is an ideal tool for measuring blasted surfaces.

Surface preparation of substrates and selecting the abrasive cleaning method to be used is essential before applying the coating. Likewise, measuring and recording the peak to valley depth that is created by the surface preparation is vital. The FMP series provides quick and repeatable measurements using the Surface Profile Probe. Having this probe on a separate cable allows for readings to be taken in areas where built-in-probes are inaccessible. Measurements are in accordance with ASTM D4417 – Method B as well as other international standards.

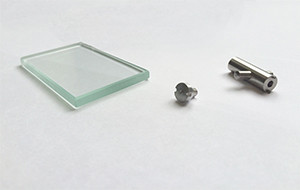

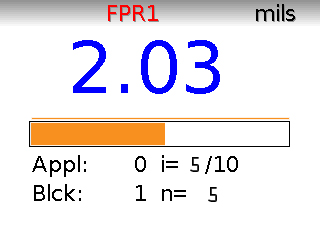

FISCHER’s Surface Profile Probe is made of an extremely rugged carbide, and offers the user the flexibility of replacing the tip in the field. The large color display with progress bar for tracking the number of required measurements per area provides the user with updated statistical data and all of the results can be uploaded to the FISCHER DataCenter Software.

A glass zero plate and a 19.5 mils ceramic precision calibration shim are included.

Features:

- Separate probe with 60° angle

- Probe tip field replaceable

- Highly repeatable and precise

- Large color display

- Progress bar for required no. of measurements

- Automatic maximum mean results

- Calculation for area readings

Specifications:

- Range: 0-500 μm (0-19.5 mils)

- Accuracy:

- up to 100 μm (4 mils): ≤ 3 μm (0.12 mils)

- 100-500 μm (4-19.5 mils): ≤ 3% of the meas. value

Conforms with: ASTM D4417, Method B, SSPC PA17, AS 3894.5-C, U.S. NAVY NSI 009-32, SANS 5772 and others.

Surface Profile Probe FPR1

Replaceable Probe Tip and Glass Zero Plate

Visible Progress Bar

The FISCHER FPR1